In today's fast-paced business landscape, problem-solving is paramount. Identifying the root cause of an issue, rather than merely addressing its symptoms, is crucial for long-term success. But how do you effectively dissect complex problems and pinpoint their origins? Enter the Ishikawa diagram, a powerful visual tool that helps teams collaboratively explore and understand the underlying factors contributing to a specific problem. This comprehensive guide will equip you with the knowledge and skills to effectively construct and utilize Ishikawa diagrams, also known as fishbone diagrams or cause-and-effect diagrams.

Constructing an Ishikawa diagram, sometimes referred to as building an Ishikawa framework or developing an Ishikawa model, is a structured process. It's not about simply brainstorming ideas; it's about systematically categorizing potential causes and drilling down to the core issues. This method allows teams to move beyond superficial solutions and address the fundamental reasons behind recurring problems, ultimately preventing their recurrence.

The Ishikawa diagram was developed by Kaoru Ishikawa, a Japanese quality control expert, in the 1960s. Initially used in manufacturing, its effectiveness quickly spread across various industries, from healthcare to software development. Its enduring popularity stems from its simplicity and ability to facilitate collaborative problem-solving. The diagram’s visual nature allows teams to readily grasp complex relationships between potential causes and the ultimate effect, making it a valuable tool for group brainstorming sessions.

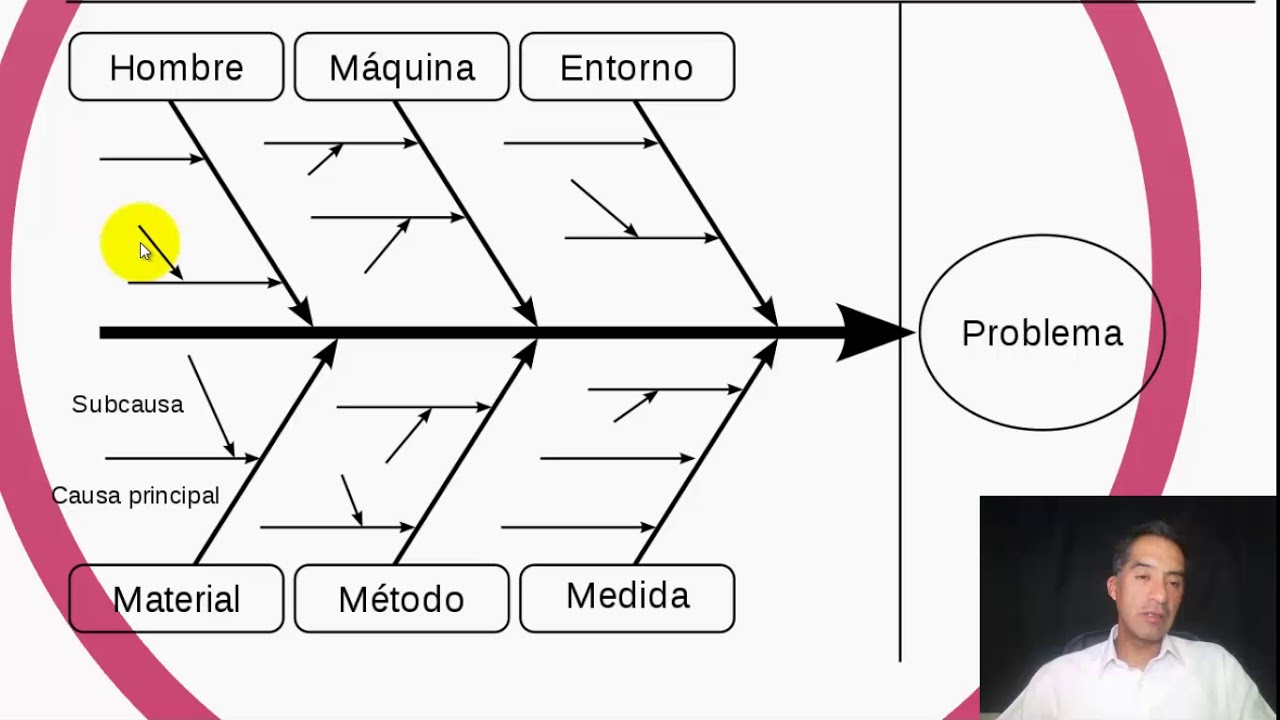

The core principle of creating an Ishikawa diagram, or executing Ishikawa diagram construction, is to identify the main categories of potential causes. These categories typically include factors like people, processes, equipment, materials, environment, and management. By organizing potential causes under these headings, teams gain a more structured approach to brainstorming and analysis. This structured approach avoids the common pitfall of focusing on symptoms rather than root causes.

Understanding the importance of proper Ishikawa diagram development is key to successful problem-solving. A poorly constructed diagram can lead to inaccurate conclusions and ineffective solutions. One common issue is failing to drill down deep enough into the potential causes. Teams may identify superficial factors without exploring the underlying reasons behind them. Another challenge is neglecting to involve all relevant stakeholders in the diagram creation process, which can lead to a limited perspective and missed opportunities for insight.

To construct an Ishikawa diagram, start by clearly defining the problem you are trying to address. Write this problem statement at the "head" of the fishbone. Then, identify the main categories of potential causes. These will form the "bones" of the fish. Brainstorm potential causes within each category, adding them as smaller "bones" branching off the main ones. Continue to break down these causes into sub-causes until you reach the root of the problem.

Benefits of using Ishikawa Diagrams include improved teamwork and collaboration, enhanced root cause identification leading to more effective solutions, and a clear visual representation of complex problems which facilitates understanding and communication. For example, a manufacturing company might use an Ishikawa diagram to analyze the causes of defects in a product. A software development team might use it to investigate the reasons for bugs in their code. A hospital might utilize it to understand the contributing factors to patient readmissions.

Best practices for implementing Ishikawa diagrams include: Clearly defining the problem, involving all relevant stakeholders, brainstorming thoroughly, prioritizing potential causes, and verifying the root causes through data analysis.

Advantages and Disadvantages of Ishikawa Diagrams

| Advantages | Disadvantages |

|---|---|

| Visually appealing and easy to understand | Can become overly complex for multifaceted problems |

| Facilitates team collaboration and brainstorming | May not effectively address problems with interconnected causes |

Challenges in implementing Ishikawa diagrams might include resistance from team members unfamiliar with the technique, difficulty in reaching consensus on the root causes, and lack of data to validate the findings. Solutions to these challenges include providing training on the method, facilitating open communication and discussion, and implementing data collection strategies.

Frequently Asked Questions: 1. What is an Ishikawa diagram? 2. How do I create one? 3. What are the benefits? 4. What are the common categories of causes? 5. What are some examples of its use? 6. How can I overcome challenges in implementing it? 7. What are some best practices? 8. How do I know if I've identified the true root cause?

Tips and tricks for constructing Ishikawa diagrams include using sticky notes for brainstorming, focusing on "why" questions to drill down to root causes, and regularly reviewing and updating the diagram as new information emerges.

In conclusion, mastering the art of constructing and interpreting Ishikawa diagrams is an invaluable skill for anyone involved in problem-solving. From identifying the root causes of manufacturing defects to unraveling the complexities of software bugs, this versatile tool empowers teams to move beyond surface-level solutions and address the core issues hindering their success. By understanding the history, principles, and best practices of Ishikawa diagram construction, individuals and organizations can unlock a more effective and efficient approach to problem-solving, fostering a culture of continuous improvement and innovation. Embrace the power of the fishbone diagram, and transform your approach to tackling challenges today. By incorporating this technique into your problem-solving toolkit, you'll be well-equipped to identify the root causes of issues and implement lasting solutions.

Top 79 imagen modelo de ishikawa - The Brass Coq

Diagrama De Ishikawa Diagrama De Espinha De Peixe Diagrama De Causa - The Brass Coq

Crea análisis impactantes con la plantilla de diagrama de causa y - The Brass Coq

como montar o ishikawa - The Brass Coq

como montar o ishikawa - The Brass Coq

Diagrama De Ishikawa Ejemplo - The Brass Coq

Espinha De Peixe Diagrama - The Brass Coq

Introduzir 122 imagem modelo de ishikawa - The Brass Coq

Como Aplicar O Diagrama De Ishikawa Para Resolver Problemas - The Brass Coq

Espinha de Peixe Ishikawa ou 6M O que é e como fazer - The Brass Coq

Diagrama de Ishikawa O Que É e Como Fazer - The Brass Coq

Total 37 imagen modelo de kaoru ishikawa - The Brass Coq

Diagrama de Ishikawa O Que é Para Que e Como Usar em Sua Empresa - The Brass Coq

Diagrama de Ishikawa O que é como montar e vantagens de usar - The Brass Coq

Diagrama De Causa Raiz - The Brass Coq