Imagine a world where the smallest discrepancies could cause catastrophic failures. A bridge whose supports are just millimeters off, a turbine whose gears don't mesh precisely, a lock whose key doesn't quite turn. In the realm of engineering and manufacturing, precision isn't merely a desirable trait; it's the bedrock upon which functionality and safety are built. And in this pursuit of exactness, standardized measurements, such as metric key stock sizes, emerge as unsung heroes.

Key stock, those seemingly humble rectangular pieces of metal, play a crucial role in transmitting torque between shafts and hubs. Their dimensions, dictated by established metric standards, ensure a secure and reliable connection, preventing slippage and ensuring the smooth operation of countless mechanical systems. From the smallest household appliance to the largest industrial machinery, the precision of metric key stock dimensions is silently at work, enabling the intricate dance of gears, pulleys, and shafts that power our modern world.

The adoption of metric key stock sizes represents a triumph of standardization, a testament to the power of shared understanding. Before the widespread adoption of the metric system, a chaotic array of measurement systems hampered international collaboration and hindered progress. The metric system, with its elegant decimal logic, provided a universal language for measurement, facilitating collaboration, accelerating innovation, and paving the way for more efficient and reliable manufacturing processes.

Understanding the nuances of metric key stock dimensions is crucial for anyone involved in design, manufacturing, or maintenance of mechanical systems. Selecting the correct key stock size ensures optimal power transmission, minimizes wear and tear, and prevents premature failure. A seemingly small error in key stock selection can have significant consequences, impacting performance, safety, and ultimately, the bottom line.

This exploration into the world of metric key stock sizes will delve into the history and importance of these standardized dimensions. We'll examine the benefits they offer, address common challenges, and provide practical guidance for selecting and implementing the appropriate key stock for any application. Whether you're a seasoned engineer or a curious novice, this guide will equip you with the knowledge and understanding to appreciate the significance of these often overlooked components.

The history of standardized key stock dimensions is intertwined with the broader adoption of the metric system. As global trade expanded, the need for a unified system of measurement became increasingly apparent. The metric system, with its inherent simplicity and logical structure, emerged as the preferred solution. This standardization extended to key stock, enabling manufacturers worldwide to produce and utilize interchangeable components.

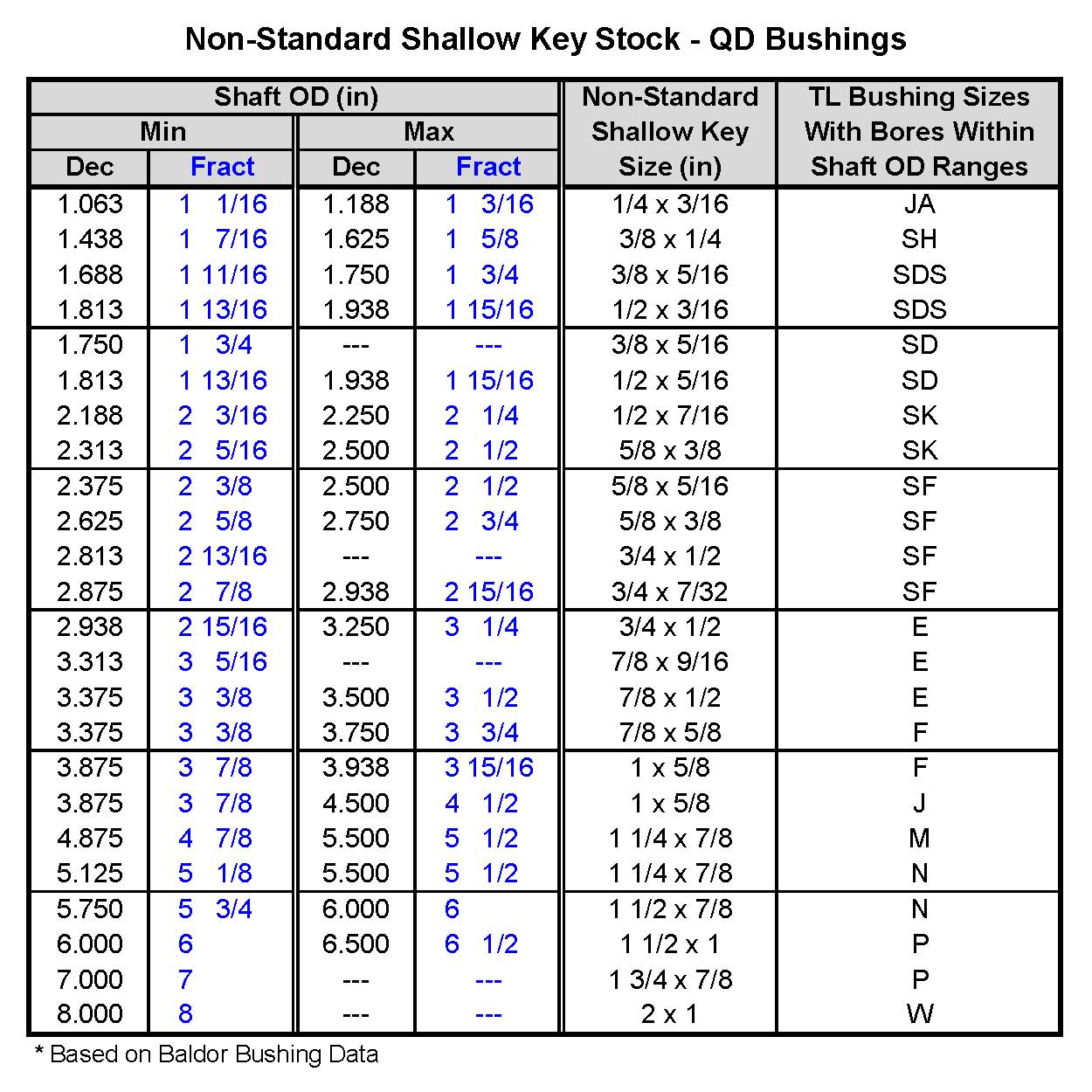

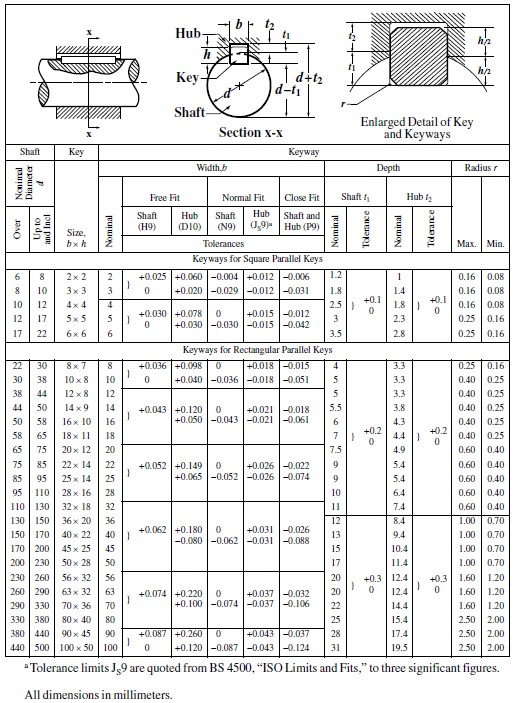

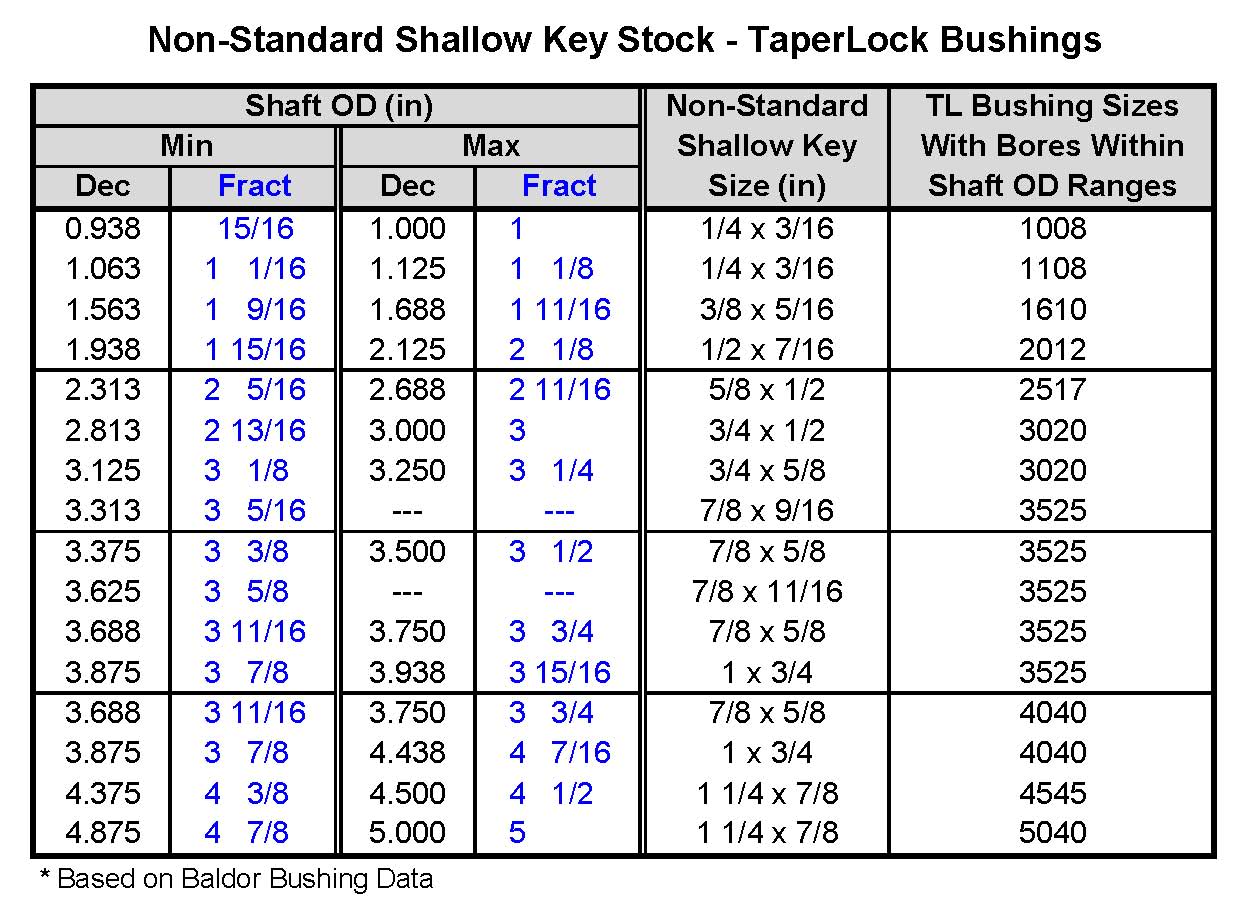

Metric key stock sizes are designated by a series of letters and numbers that correspond to specific dimensions, such as width, height, and length. These standardized sizes ensure compatibility between shafts and hubs, simplifying design and assembly processes.

Three key benefits of using metric key stock sizes are interchangeability, simplified design, and reduced manufacturing costs. Interchangeability allows components from different manufacturers to be seamlessly integrated. Simplified design processes result from standardized dimensions, and reduced manufacturing costs are achieved through economies of scale and streamlined production.

Choosing the correct metric key stock size involves considering factors like shaft diameter, torque requirements, and material properties. Consulting engineering handbooks and manufacturer catalogs can provide valuable guidance in selecting the appropriate dimensions.

Advantages and Disadvantages of Metric Key Stock

| Advantages | Disadvantages |

|---|---|

| International standardization | Potential incompatibility with legacy systems |

| Simplified design | Limited availability of certain sizes in some regions |

| Interchangeability |

Five best practices for implementing metric key stock include proper keyway machining, accurate key fitting, secure fastening, regular inspection, and appropriate lubrication.

Frequently asked questions about metric key stock often pertain to material selection, size compatibility, installation procedures, and troubleshooting common issues.

Tips and tricks for working with metric key stock include using precision measuring tools, ensuring proper alignment during installation, and applying appropriate lubricants to minimize friction and wear.

In conclusion, the seemingly small details of metric key stock sizes underpin the functionality of countless mechanical systems. Their standardized dimensions ensure precision, interchangeability, and reliability, enabling the smooth operation of everything from household appliances to complex industrial machinery. Understanding the nuances of metric key stock selection and implementation is essential for anyone involved in design, manufacturing, or maintenance of these vital systems. By embracing these standardized dimensions, we unlock a world of precision and efficiency, ensuring the seamless operation of the machines that power our modern world. As we move forward, continued adherence to these standards will be crucial for maintaining interoperability, driving innovation, and ensuring the reliability of future technologies. Take the time to understand the specifics of your application and choose the right metric key stock size – the benefits in terms of performance, longevity, and cost-effectiveness are well worth the effort.

Standard Keyway Size Chart - The Brass Coq

Key Stock Size Chart - The Brass Coq

Metric Shaft Keyway Dimensions Pdf at amyjstreatero blog - The Brass Coq

Metric Key Stock Sizes - The Brass Coq

Woodruff Key Size Chart Metric - The Brass Coq

Metric Key Stock Sizes - The Brass Coq

Standard Key Bar Sizes at Tiffany Penick blog - The Brass Coq

Standard Keyway Size Chart - The Brass Coq

Metric Step Key Stock Sizes - The Brass Coq

metric key stock sizes - The Brass Coq

Shaft Key Standard Dimensions at Claude Rondon blog - The Brass Coq

Rectangular Key Stock Sizes - The Brass Coq

Standard Key Size For Shaft Chart - The Brass Coq

metric key stock sizes - The Brass Coq

Drive Shaft Key Sizes at Earl Surrett blog - The Brass Coq