Hauling your boat shouldn't feel like dragging an anchor. The right wheel bearings can make all the difference, and increasingly, boat owners are turning to the smooth, reliable performance of oil-filled bearings. But are they right for you? This comprehensive guide explores everything you need to know about oil-filled wheel bearings for boat trailers, from their inner workings to their long-term benefits.

Imagine effortlessly gliding your boat down the highway, confident that your trailer is operating at peak efficiency. This isn't a fantasy; it's the promise of properly maintained oil-filled trailer bearings. These sealed units offer a significant advantage over traditional grease-packed bearings, particularly for boat trailers frequently submerged in water. They provide superior lubrication and protection against corrosion, the bane of any boat trailer owner.

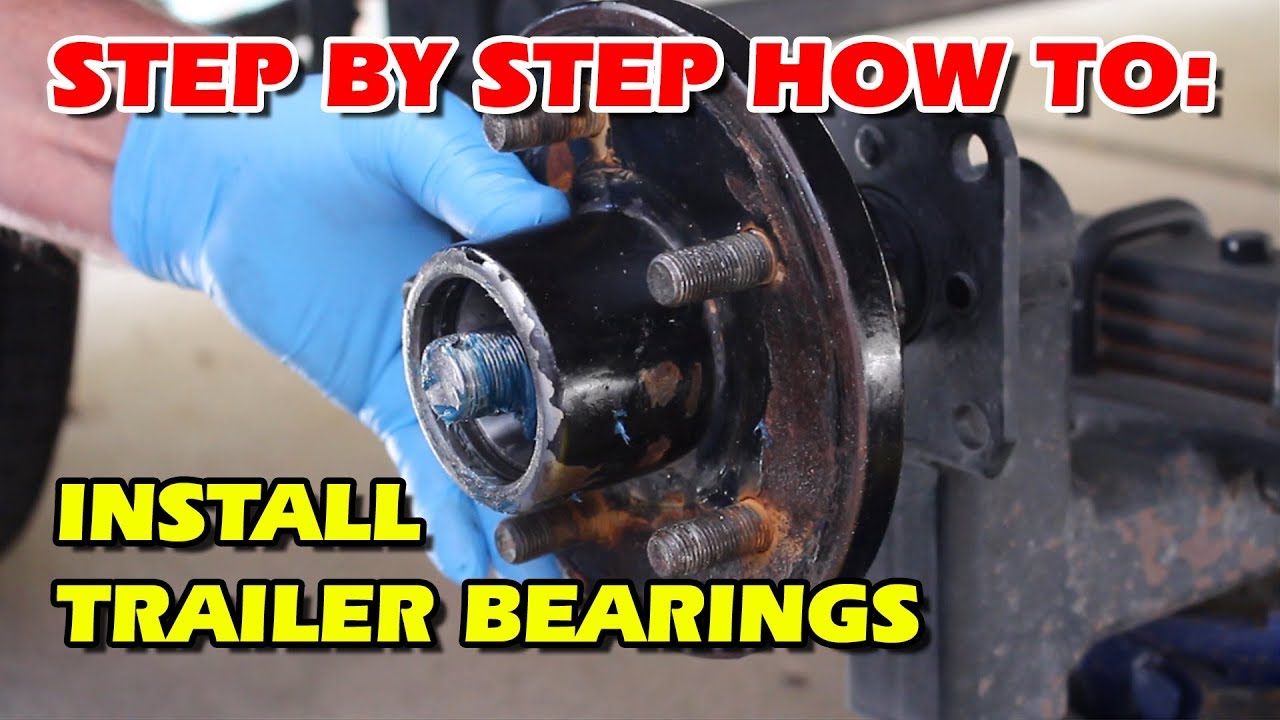

Traditional grease-packed bearings, while serviceable, are prone to water intrusion and subsequent corrosion. This can lead to premature failure, requiring frequent repacking and potential roadside emergencies. Oil-filled bearings, also known as oil bath bearings, address these issues by creating a sealed environment filled with lubricating oil. This barrier effectively keeps water and contaminants out, ensuring smooth operation and extending the lifespan of the bearings.

The shift towards oil-filled bearings reflects a broader trend in trailer technology: a move toward lower maintenance and increased reliability. For boat trailers, this is particularly crucial. The harsh marine environment, combined with the stresses of launching and retrieving a boat, demands robust and dependable components. Oil-filled bearings rise to this challenge, offering a worry-free solution that allows boaters to focus on what matters most: enjoying time on the water.

While the precise origin of oil-filled bearings is difficult to pinpoint, their adoption in the boating world is relatively recent. As boaters sought more reliable and less maintenance-intensive solutions for their trailers, the advantages of oil-filled bearings became clear. Their increasing popularity speaks volumes about their effectiveness in mitigating the challenges posed by the marine environment.

One of the primary benefits of oil-filled bearings for boat trailers is their enhanced corrosion resistance. The sealed design prevents water and saltwater from entering the bearing cavity, thus protecting the internal components from rust and deterioration. This is particularly important for boat trailers, which are frequently exposed to harsh marine environments.

Another advantage is reduced maintenance. Unlike grease-packed bearings, which require regular repacking, oil-filled bearings are sealed and require minimal upkeep. This translates to less time spent on maintenance and more time on the water.

Finally, oil-filled bearings generally offer improved performance and longevity. The constant lubrication provided by the oil bath reduces friction and heat, leading to smoother operation and a longer lifespan for the bearings.

Advantages and Disadvantages of Oil-Filled Bearings

| Advantages | Disadvantages |

|---|---|

| Reduced Maintenance | Higher Initial Cost |

| Improved Corrosion Resistance | More Complex Installation (Potentially) |

| Enhanced Durability and Longevity | Limited Repair Options - Often Requires Full Replacement |

Best Practices for Implementing Oil Filled Wheel Bearings:

1. Choose the correct bearing size and capacity for your trailer.

2. Ensure proper installation following manufacturer guidelines.

3. Inspect bearings regularly for any signs of damage or leaks.

4. Avoid overfilling or underfilling the oil reservoir.

5. Replace bearings at recommended intervals or if any issues are detected.

Frequently Asked Questions:

1. How often should I inspect my oil-filled bearings? - Annually or more frequently if used in harsh conditions.

2. What type of oil should I use? - Consult your bearing manufacturer's recommendations.

3. Can I convert my existing grease-packed bearings to oil-filled? - In some cases, yes, but it's best to consult a professional.

4. Are oil-filled bearings more expensive than grease-packed bearings? - Typically, yes, but the long-term cost savings from reduced maintenance can offset this.

5. How do I know if my oil-filled bearings need to be replaced? - Signs of wear, leaks, or excessive noise indicate potential problems.

6. Where can I buy oil-filled wheel bearings for my boat trailer? - Marine supply stores, online retailers, and trailer parts specialists.

7. Are there different brands of oil-filled bearings? - Yes, several reputable manufacturers offer oil-filled bearings for trailers.

8. Can I install oil-filled bearings myself? - Yes, if you have mechanical experience, but professional installation is recommended for optimal results.

Tips and Tricks:

Keep a spare set of bearings on hand for emergencies.

Inspect bearings after each submersion in saltwater.

Use a high-quality marine-grade oil for optimal performance.

In conclusion, oil-filled wheel bearings offer a compelling upgrade for boat trailers, providing superior protection against corrosion, reduced maintenance requirements, and enhanced performance. While the initial cost might be higher than grease-packed bearings, the long-term benefits in terms of reliability and reduced downtime make them a worthwhile investment. By understanding the advantages, following best practices, and addressing potential challenges proactively, boat owners can ensure smooth sailing on the road and on the water. Investing in high-quality oil-filled bearings ensures not only the longevity of your trailer but also peace of mind, allowing you to focus on the joys of boating rather than the worries of potential roadside breakdowns. Take the plunge and experience the difference these innovative bearings can make in your boating adventures.

Changing boat trailer wheel bearings - The Brass Coq

Installing Trailer Wheel Bearing - The Brass Coq

Trailer Wheel Bearing Diagram - The Brass Coq

Boat Trailer Axle Sizes at Brad Evans blog - The Brass Coq

DIAGRAM Ford Ranger Lubrication Diagram - The Brass Coq

How Do You Bleed Surge Brakes at Joyce Rickel blog - The Brass Coq

Boat Trailer Wheel Bearing Grease at Thomas Hightower blog - The Brass Coq

How To Pack A Trailer Wheel Bearing With Grease at Phyllis Hintz blog - The Brass Coq

Ranger Boat Trailer Cool Hub Diagram - The Brass Coq

Fitting Trailer Wheel Bearings - The Brass Coq

Oil Bath Boat Trailer Bearings Oil Change - The Brass Coq

Maintaining Boat Trailer Wheel Bearings at Dorothy Hirsch blog - The Brass Coq

What Grease To Use On Wheel Hub at Benjamin Lipp blog - The Brass Coq

Ranger Trail Trailer Parts Diagram - The Brass Coq

How Do You Grease The Wheel Bearings On A Travel Trailer at Scott - The Brass Coq