Ever wondered how to transform simple household items into a miniature speed machine? Creating a rubber band powered car is a classic STEM activity that blends creativity, engineering principles, and good old-fashioned fun. This comprehensive guide will take you through everything you need to know about designing, building, and racing your own rubber band car, from beginner basics to expert tips.

Constructing a rubber band powered vehicle isn't just about assembling parts; it's about understanding the science behind the motion. The potential energy stored in a wound-up rubber band converts into kinetic energy, propelling the car forward. This hands-on experience teaches fundamental physics concepts in an engaging way. Whether you're a parent looking for a fun educational project, a teacher seeking engaging classroom activities, or simply someone who enjoys tinkering, a rubber band car offers an exciting challenge.

The origins of rubber band powered cars can be traced back to the early 20th century when rubber bands became readily available. Initially simple toys, these vehicles evolved into popular science projects and even competitive racing events. Today, designing a rubber band powered car remains a timeless activity, fostering problem-solving skills and sparking an interest in engineering.

One of the key issues when crafting a rubber band powered car lies in optimizing its performance. Factors like the car's weight, aerodynamics, and the type of rubber band used significantly impact its speed and distance traveled. This challenge encourages experimentation and critical thinking to achieve the best possible results. Beyond the technical aspects, assembling a rubber band powered vehicle fosters creativity, allowing for personalized designs and unique modifications.

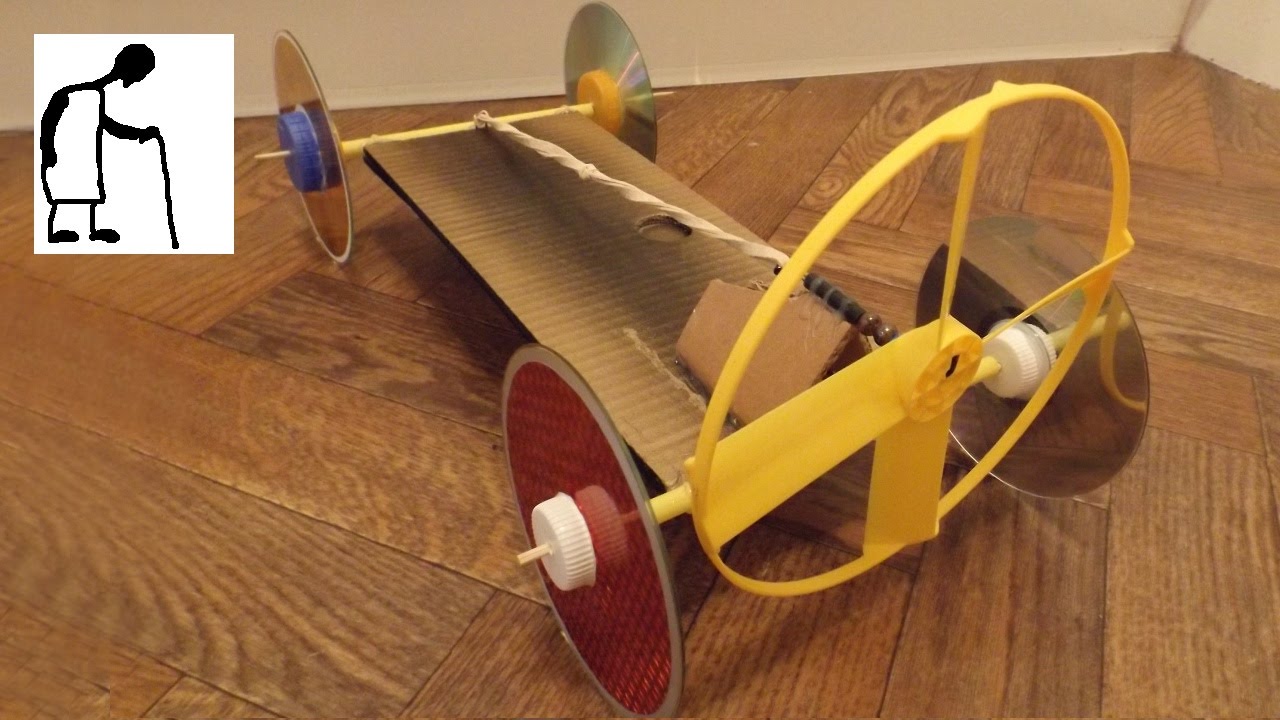

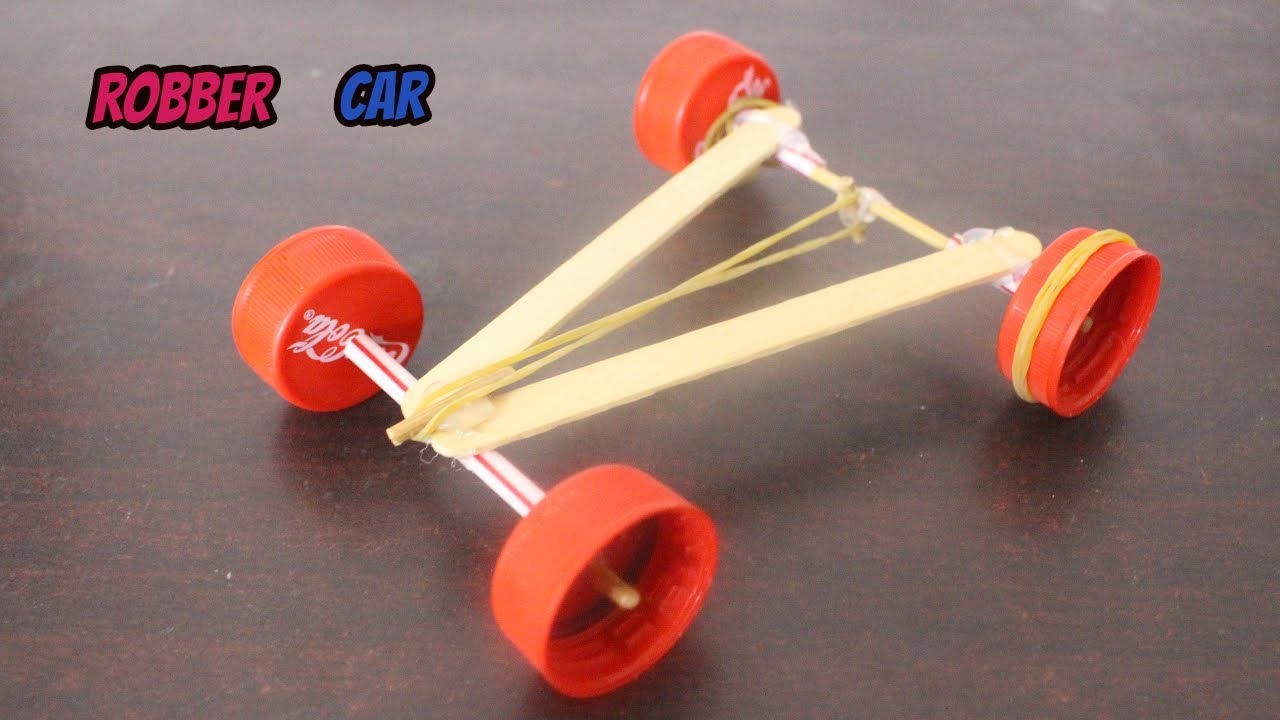

Building a rubber band powered car is a remarkably accessible activity. Simple designs require readily available materials like cardboard, skewers, straws, and rubber bands. More sophisticated designs can incorporate lightweight woods like balsa, plastic wheels, and even 3D-printed parts, offering endless possibilities for customization and innovation.

Benefits of constructing these mini-vehicles include developing problem-solving skills, understanding basic physics principles, and fostering creativity. These projects also provide a fantastic opportunity for hands-on learning, bridging the gap between theory and practical application.

Creating your own rubber band car is a simple process. Start by designing a chassis from cardboard or wood. Attach axles using skewers or straws, and then mount wheels. The crucial part is the propulsion system: secure a hook or loop to the rear axle to attach the rubber band. Winding the rubber band around the axle stores the energy that will drive the car forward.

Advantages and Disadvantages of Rubber Band Powered Cars

| Advantages | Disadvantages |

|---|---|

| Eco-friendly and uses no batteries | Limited range and speed |

| Affordable and uses readily available materials | Performance can be affected by temperature and humidity |

| Educational and promotes STEM learning | Can be fragile depending on construction materials |

Best Practices:

1. Use lightweight materials for the chassis.

2. Ensure the axles are straight and rotate freely.

3. Experiment with different rubber band sizes and thicknesses.

4. Aerodynamic designs can improve performance.

5. Test and adjust your design iteratively.

Frequently Asked Questions:

1. What type of rubber bands work best? Thicker rubber bands generally provide more power.

2. How can I make my car go faster? Reduce weight, improve aerodynamics, and use a powerful rubber band.

3. What materials can I use for the wheels? CDs, bottle caps, or commercially available wheels are good options.

4. How do I attach the axles? Use straws, skewers, or small dowels.

5. Can I decorate my car? Absolutely! Let your creativity shine.

6. Where can I find more information on building rubber band cars? Online tutorials, science books, and educational websites are great resources.

7. What are some common problems with rubber band cars? Axles slipping, rubber bands breaking, and wheels not turning freely are common issues.

8. How can I troubleshoot these problems? Ensure axles are securely attached, use strong rubber bands, and lubricate the axles if necessary.

Tips and Tricks: Consider using lightweight wheels and ensuring your axles are properly aligned. Experimenting with different rubber band lengths and thicknesses can dramatically affect performance. A little lubrication on the axles can also reduce friction and improve speed.

Building a rubber band powered car offers a rewarding experience that combines creativity, engineering principles, and hands-on learning. From simple designs to more complex models, the possibilities are endless. Whether you’re aiming for speed, distance, or simply a fun afternoon project, crafting a rubber band vehicle provides a tangible connection to scientific concepts and encourages problem-solving skills. This journey from a simple collection of materials to a functional mini-vehicle is not just about building a toy; it's about building knowledge, fostering innovation, and sparking a lifelong love of learning. So gather your materials, unleash your creativity, and embark on the exciting adventure of building your very own rubber band powered car!

Elastic Band Fan at Elizabeth Moree blog - The Brass Coq

How to Make a Rubber Band Car Inspiring Teaching Ideas - The Brass Coq

Rubber Band Car Examples - The Brass Coq

ști barcă verb rubber band car Regină platformă iunie - The Brass Coq

build a rubber band powered car - The Brass Coq

Rubber Band Racing Cars - The Brass Coq

Build A Rubber Band Powered Car - The Brass Coq

rubber band powered car - The Brass Coq

Wheels Toy Car Project at Gregory Reed blog - The Brass Coq

Rubber Band Car Science Fair Project - The Brass Coq

Diy Rubber Band Car - The Brass Coq

Rubber Band Car Diy - The Brass Coq

How To Make a Mini Latch Rubber Band Car - The Brass Coq

Rubber Band Car Designs For Distance - The Brass Coq

How To Make Rubber Band Engine at Fern Parker blog - The Brass Coq