Imagine smoothly lifting your boat out of the water with the push of a button. That's the promise of a properly wired boat lift. But getting the electrical connections right, especially for a 220-volt 1 HP motor, is crucial. This isn't just about convenience; it's about safety and the longevity of your equipment.

Wiring a 220V 1 HP boat lift motor might seem daunting, but with the right knowledge and preparation, it's a manageable task. This comprehensive guide will break down the process, offering insights into everything from understanding the basics of 220V circuits to troubleshooting common wiring problems. Whether you're a seasoned DIYer or a newcomer to electrical work, this information will empower you to power your boat lift correctly.

The evolution of boat lift motors mirrors advancements in electric motor technology. Early boat lifts relied on manual winches or less powerful motors. The rise of more robust and efficient 1 HP motors, coupled with the availability of 220V power, has revolutionized the boat lifting experience, allowing for quicker and more reliable operation. Correct 220v 1 hp boat lift motor wiring is key to tapping into this power.

Understanding the importance of proper wiring is paramount. An incorrectly wired motor can lead to a range of issues, from tripped breakers and motor damage to dangerous electrical shocks. This is why adhering to safety regulations and best practices is non-negotiable when dealing with 220V circuits and boat lift motor wiring diagrams. Getting the wiring right ensures the safety of you and your equipment, while maximizing the performance and lifespan of your boat lift.

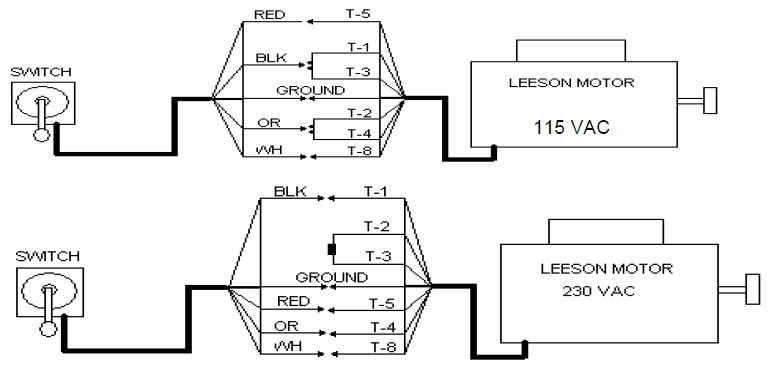

Before starting any electrical work, disconnect the power supply to the boat lift. Always double-check that the power is off using a voltage tester. This is the most critical safety precaution when dealing with any electrical circuit, especially a 220V circuit. Safety glasses and insulated gloves should also be worn throughout the process. Using a 240 volt 1hp motor wiring schematic for your specific motor model is crucial.

One benefit of a correctly wired 220V 1 HP motor is increased lifting power and speed compared to lower voltage options. Another benefit is improved motor efficiency, leading to lower energy consumption and operating costs. Finally, correct wiring minimizes the risk of motor damage and extends its lifespan.

A step-by-step guide, including using a proper wiring diagram specific to your motor model, and following all local electrical codes, should be consulted. Consult a qualified electrician if needed.

Advantages and Disadvantages of 220V 1 HP Boat Lift Motors

| Advantages | Disadvantages |

|---|---|

| More lifting power | Requires 220V circuit, which may not be readily available |

| Faster lifting speed | More complex wiring than 110V motors |

| Increased efficiency | Higher potential for electrical shock if wired incorrectly |

Best practices include using appropriate gauge wiring for the motor's amperage draw, ensuring proper grounding, using weatherproof connections, and regularly inspecting the wiring for damage.

Troubleshooting common problems such as tripped breakers or motor failure often involves checking the wiring connections, ensuring the correct voltage supply, and verifying the motor's internal components.

FAQs:

Q: What gauge wire should I use? A: Consult your motor's specifications and local electrical codes.

Q: Do I need a GFCI? A: Yes, GFCI protection is crucial for safety near water.

Q: Can I convert a 110V motor to 220V? A: Generally, no. Motors are designed for specific voltages.

Q: What type of wiring should I use for outdoor installations? A: Use marine-grade, tinned copper wire rated for outdoor use.

Q: How do I test the motor after wiring? A: Briefly activate the lift to ensure proper operation in both directions.

Q: Where can I find a wiring diagram for my specific motor? A: Consult the motor manufacturer's documentation.

Q: What are common wiring mistakes to avoid? A: Reversed polarity, loose connections, and improper grounding.

Q: Should I hire an electrician? A: If you're unsure about any aspect of the wiring, consult a qualified electrician.

Tips and Tricks: Always disconnect the power before working on the motor. Use wire connectors rated for the wire gauge and voltage. Label all wires clearly. Document your wiring with photos and diagrams.

Wiring a 220V 1 HP boat lift motor correctly is an essential task for any boat owner. It's about ensuring safety, maximizing the performance of your lift, and extending the life of your motor. By understanding the principles of 220V circuits, following best practices, and taking the necessary safety precautions, you can confidently tackle this project and enjoy the convenience and peace of mind that comes with a properly wired boat lift. Remember, when it comes to electricity and water, safety is paramount. If you are unsure about any aspect of the wiring process, consulting a qualified electrician is always the best course of action. This investment in professional guidance can save you time, money, and potential hazards in the long run, ensuring your boat lift operates smoothly and safely for years to come.

Ao Smith Boat Lift Motor Wiring Diagram - The Brass Coq

jasnoća siromaštvo brak electric lift motor Mekana stopala Glumac - The Brass Coq

Single Phase 220 Volt Wiring Diagram - The Brass Coq

wiring a 220 1 hp boat lift motor - The Brass Coq

Ao Smith Boat Lift Motor Wiring Diagram - The Brass Coq

Wiring Diagram For Boat Lift Motor - The Brass Coq

15 HP Replacement Boat Lift Motor - The Brass Coq

Elite 1 HP Boat Lift Motors Elite Boat Lift Motors - The Brass Coq

Boat Hoist Usa Wiring Diagrams - The Brass Coq

Wiring A Boat Lift - The Brass Coq

The Best Ao Smith 1 Hp Boat Lift Motor - The Brass Coq

Boat Lift Motor Wire - The Brass Coq

Radio Control Boat Wiring Diagrams Wiring Draw And Schematic - The Brass Coq

Bremas Boat Lift Switch Wiring Diagram - The Brass Coq

How To Wire A Boat Lift Motor - The Brass Coq