Stopping a behemoth like the Ford F-350 requires a robust and precisely calibrated braking system. The power behind those brakes lies in understanding and applying the correct torque specifications. Ignoring these specifications can lead to anything from annoying squeaks to catastrophic brake failure. Are you confident you're giving your F-350 brakes the attention they deserve?

This comprehensive guide delves into the intricacies of Ford F-350 brake torque specifications. We'll cover everything from the basic principles of torque to advanced troubleshooting techniques, empowering you to maintain your truck's braking system with confidence. Whether you're a seasoned mechanic or a weekend warrior, understanding these specifications is paramount to ensuring your safety and the longevity of your F-350's braking components.

From lug nuts to caliper bolts, each component in your F-350's braking system has a specific torque requirement. These specifications are meticulously engineered by Ford to ensure optimal clamping force, prevent premature wear, and guarantee the integrity of the entire system. Using the correct torque values is akin to fine-tuning a musical instrument – each adjustment contributes to a harmonious and effective performance.

Over-tightening a bolt can lead to stripped threads, warped rotors, or even component failure. Under-tightening, on the other hand, can cause vibrations, looseness, and ultimately, a loss of braking power. This guide will provide you with the knowledge and resources to avoid these pitfalls and maintain your F-350's braking system in peak condition.

Navigating the world of Ford F-350 brake torque specifications can be daunting. Where do you find the correct values? What tools do you need? How do you apply them correctly? We'll address these questions and more, providing you with a practical roadmap to mastering your F-350's braking system.

Historically, brake systems have evolved from simple mechanical linkages to complex hydraulic and electronic systems. Torque specifications have become increasingly critical with this evolution. For the F-350, these specifications reflect the truck's heavy-duty nature and the demanding conditions it often faces. Correct torque application is essential for maintaining stopping power, especially when towing or hauling heavy loads.

Torque, in the context of brakes, refers to the rotational force applied to a fastener. It's measured in pound-feet (lb-ft) or Newton-meters (Nm). Applying the correct torque ensures that the fastener is tightened just enough to secure the component without causing damage. For example, over-torquing a caliper bolt can warp the caliper and lead to uneven brake pad wear.

One key benefit of adhering to Ford F-350 brake torque specifications is enhanced safety. Properly torqued components contribute to a reliable and predictable braking system, reducing the risk of accidents. Another advantage is improved component longevity. Correct torque prevents stress and wear on brake parts, extending their lifespan and saving you money on repairs. Finally, proper torque application contributes to smoother braking performance, eliminating vibrations and noises that can indicate loose or over-tightened components.

Advantages and Disadvantages of Adhering to Torque Specs

| Advantages | Disadvantages |

|---|---|

| Increased Safety | Requires specific tools (torque wrench) |

| Longer Component Life | Time consuming to look up specs |

| Improved Braking Performance |

Best Practices:

1. Always consult your F-350's owner's manual for the latest torque specifications. These specs can vary depending on the model year and brake system configuration.

2. Invest in a quality torque wrench. This tool is essential for accurately applying the specified torque values.

3. Clean and lubricate threads before tightening fasteners. This prevents corrosion and ensures accurate torque readings.

4. Tighten fasteners in a crisscross pattern. This ensures even pressure distribution and prevents warping.

5. Double-check your work. After tightening all fasteners, go back and re-check the torque values to ensure they are within specification.

FAQs:

Q: Where can I find the torque specifications for my F-350's brakes?

A: Consult your owner's manual or a reputable online source like a Ford service website.

Q: What type of torque wrench should I use?

A: A calibrated click-type or beam-type torque wrench is recommended.

Q: What happens if I over-torque a brake caliper bolt?

A: You could warp the caliper, leading to uneven brake pad wear and reduced braking performance.

Q: How often should I check my F-350's brake torque specifications?

A: It's a good idea to check them every time you perform brake maintenance, such as replacing brake pads or rotors.

Q: What are the torque specs for lug nuts on an F-350?

A: Refer to your owner's manual, as these can vary by model year.

Q: Can I use a regular wrench instead of a torque wrench?

A: It's not recommended, as you won't be able to accurately apply the correct torque.

Q: Are brake torque specifications the same for all F-350 models?

A: No, they can vary depending on the model year and specific brake system.

Q: What should I do if I strip a thread while tightening a brake component?

A: Consult a qualified mechanic to assess the damage and recommend a repair.

Tips and Tricks: Use a torque chart. Keep your torque wrench calibrated. Work in a well-lit area. Double-check your work.

In conclusion, understanding and applying the correct Ford F-350 brake torque specifications is essential for maintaining a safe, reliable, and efficient braking system. By following the guidelines outlined in this guide and utilizing the correct tools, you can ensure optimal braking performance and extend the life of your F-350's braking components. Remember, proper brake maintenance is not just about replacing worn parts; it's about meticulous attention to detail, including applying the correct torque to every fastener. Don't underestimate the importance of these specifications; they are crucial for your safety and the longevity of your truck. Take the time to learn and apply these principles, and you'll be rewarded with a confident and controlled driving experience. Empower yourself with the knowledge and tools to master your F-350's braking system – it's an investment in your safety and peace of mind.

ford f350 brakes torque specifications - The Brass Coq

Does anyone know the torque values for a 1993 f350 4wd drw 73liter - The Brass Coq

Ford f350 dually rear brakes - The Brass Coq

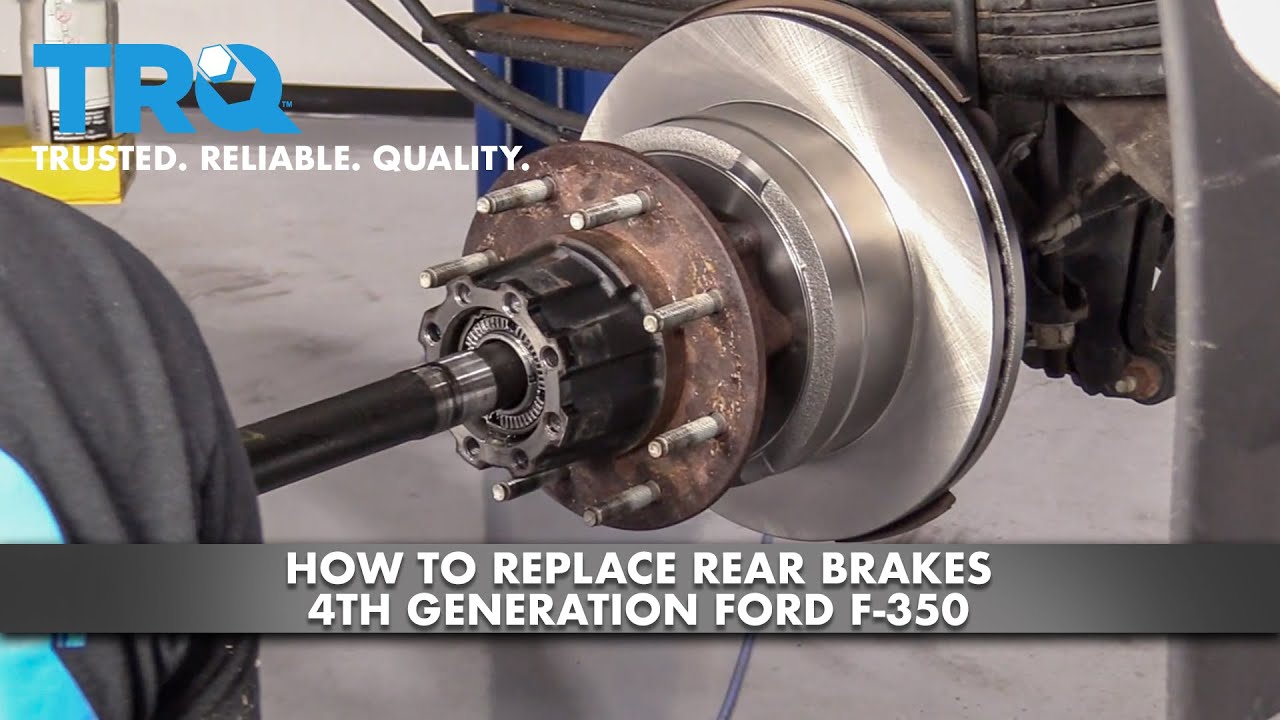

How to Replace Rear Brakes 2017 - The Brass Coq

Ford Brake Caliper Torque Specifications Chart - The Brass Coq

Ford Truck Technical Drawings and Schematics - The Brass Coq

Brake caliper torque specs ford f150 - The Brass Coq

Torque Spec For Ford Explorer Lug Nuts - The Brass Coq

Chevy Lug Nut Torque Specifications - The Brass Coq

2010 Ford F150 Wheel Torque Specs - The Brass Coq

Ford Brake Caliper Torque Specifications Chart - The Brass Coq

Lug Nut Torque Specifications - The Brass Coq

Brake Caliper Bracket Torque Specs Ford Fiesta at Joshua Brown blog - The Brass Coq

1998 Honda Accord Torque Specs - The Brass Coq

F150 Lug Torque Spec - The Brass Coq