There's a quiet confidence in knowing the language of your vessel. It's not just about navigating the open water, but also about understanding the intricate network that keeps you afloat. Among these essential systems, the bilge pump stands as a silent guardian against flooding, and its wiring, a subtle choreography of color-coded conductors, plays a vital role.

Imagine the scene: a sun-drenched deck, the gentle rocking of the hull, and the quiet hum of a well-maintained bilge pump. This peace of mind hinges on the correct interpretation of the bilge pump's wiring scheme. Each hue, a carefully chosen thread in the tapestry of your boat's electrical system, tells a story. Understanding this story is paramount for both installation and troubleshooting.

While seemingly mundane, the subject of bilge pump wire coloration is a critical aspect of boat ownership. Ignoring it could lead to malfunction, potential flooding, and ultimately, compromise the safety of your vessel. This guide aims to illuminate the significance of these color codes, providing a practical and insightful exploration into the world of bilge pump wiring.

The history of bilge pump wiring color standards is intertwined with the development of marine electrical systems. As boat designs became more complex, the need for standardized wiring practices emerged. This standardization, largely driven by organizations like the American Boat and Yacht Council (ABYC), aims to ensure compatibility and safety across different boat manufacturers and systems.

Understanding the nuances of bilge pump wire colors goes beyond simply matching hues. It involves grasping the underlying principles of electrical circuits, the function of each wire within the system, and the potential implications of incorrect connections. This knowledge empowers boat owners to perform basic maintenance, diagnose problems, and ensure the long-term reliability of their bilge pump system.

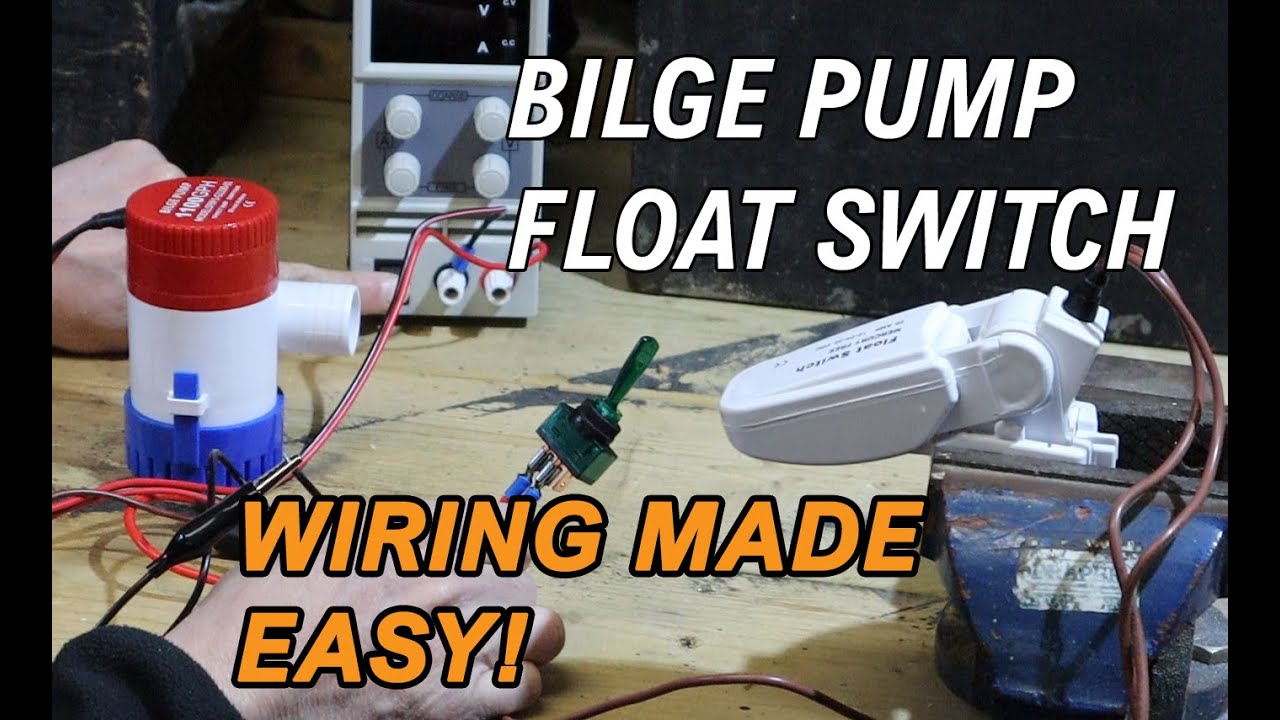

Typically, bilge pump wiring involves a few key colors. The positive wire, often red, supplies power to the pump. The negative wire, commonly black, completes the circuit. A green wire usually serves as the ground, providing a safe path for stray currents. Variations may exist depending on the manufacturer, so consulting your boat's specific wiring diagram is crucial.

Benefits of adhering to standardized bilge pump wire colors include: simplified troubleshooting, easier installation or replacement, and enhanced safety. Standardized colors allow for quick identification of wires, reducing the risk of misconnections. This clarity is invaluable during emergencies, allowing for swift diagnosis and repair of potential issues.

When working with bilge pump wiring, a systematic approach is essential. Begin by disconnecting the power supply to avoid electrical shocks. Consult the wiring diagram specific to your bilge pump model. Carefully trace each wire, noting its color and connection point. If replacing wires, use marine-grade wire designed to withstand the harsh marine environment.

Advantages and Disadvantages of Standardized Bilge Pump Wire Colors

| Advantages | Disadvantages |

|---|---|

| Simplified Troubleshooting | Potential for Confusion with Older, Non-Standard Systems |

| Easier Installation and Replacement | Variations Between Manufacturers |

| Enhanced Safety |

Best Practices for Bilge Pump Wiring: 1. Use marine-grade wiring. 2. Consult your boat's wiring diagram. 3. Securely connect all wires. 4. Use waterproof connectors. 5. Regularly inspect the wiring for damage.

FAQs: 1. What does a brown wire on a bilge pump indicate? Consult your specific wiring diagram. 2. Can I use automotive wire for my bilge pump? Marine-grade wire is recommended. 3. What if my bilge pump wires are not color-coded? Trace the wires and create a diagram. 4. How do I test my bilge pump wiring? Use a multimeter to check for continuity and voltage. 5. What should I do if my bilge pump isn't working? Check the wiring, fuse, and float switch.

Tips and Tricks: Label your bilge pump wires for future reference. Use heat shrink tubing to protect connections from moisture. Regularly inspect your bilge pump wiring for signs of corrosion or damage.

In the intricate world of boat maintenance, understanding the significance of bilge pump wire color codes is a key element of responsible ownership. From ensuring proper installation to enabling quick troubleshooting, these seemingly small details contribute significantly to the safety and reliability of your vessel. By adhering to best practices, consulting wiring diagrams, and staying informed about the nuances of bilge pump wiring, you equip yourself with the knowledge and confidence to maintain a seaworthy and secure vessel. This understanding transcends mere technical proficiency; it's about fostering a deeper connection with your boat, appreciating the interconnectedness of its systems, and embracing the responsibility that comes with navigating the open waters. Don't underestimate the power of these colorful conductors – they are the silent guardians of your maritime adventures.

Wiring A Automatic Bilge Pump - The Brass Coq

Wiring Automatic Bilge Pump - The Brass Coq

Bilge Pump Wiring Colors - The Brass Coq

How To Install A Bilge Pump And Float Switch at Josephine Neal blog - The Brass Coq

How To Wire A Float Switch For A Bilge Pump at James Belcher blog - The Brass Coq

Automatic Bilge Pump Wiring Diagram Bilge Wiring Pump Rule Switch Float - The Brass Coq

Bezahlbare Preise exzellenter Kundenservice 12V 20A MPS Auto Bilge Pump - The Brass Coq

Sump Pump Float Switch Wiring Diagram - The Brass Coq

Attwood Float Switch Wiring Diagram - The Brass Coq

How To Wire An Automatic Bilge Pump - The Brass Coq

How To Wire Float Switch To Pump - The Brass Coq

Data Wiring Color Code - The Brass Coq

How To Wire A Bilge Pump Switch - The Brass Coq

How To Hook Up A Bilge Pump Switch at Marilyn Thomas blog - The Brass Coq