Ever found yourself staring at a bolt, wondering if your 8mm wrench will fit, only to realize it's an SAE size? We've all been there. The world of fasteners can feel like a confusing mix of metric and imperial measurements, but fear not, understanding the SAE equivalent to 8mm is easier than you think.

Let's unravel this mystery. When we talk about an "SAE equivalent to 8mm," we're essentially trying to find the closest possible match in the SAE (Society of Automotive Engineers) system for an 8mm bolt or nut. The metric system, with its millimeter measurements, and the SAE system, using inches and fractions thereof, are the two dominant standards in fasteners. While they don't have a perfect one-to-one conversion, with a little guidance, you'll be switching between them like a pro.

The need for understanding both systems is paramount, especially in fields like automotive repair, where vehicles often use a mix of metric and SAE fasteners. Imagine working on your car's brakes and needing to loosen an 8mm bolt but only having SAE wrenches on hand – a frustrating situation to say the least! This is where knowing your equivalents comes in handy.

But why are there two different systems in the first place? The answer lies in history and geography. The metric system, with its decimal-based ease, gained popularity in Europe, while the United States leaned towards the SAE system. This divide, while seemingly simple, has led to a world where knowing your conversions can mean the difference between a successful project and a toolbox full of frustration.

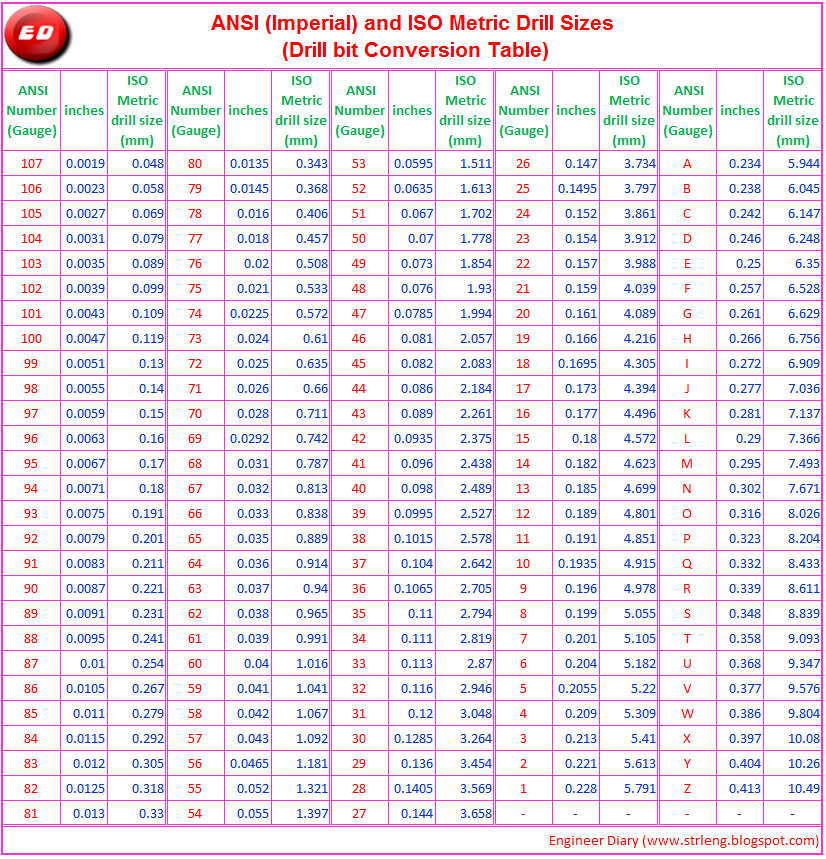

So, how do you decipher the SAE equivalent to 8mm? While a direct conversion isn't always precise, a 5/16-inch wrench is generally considered the closest SAE equivalent to an 8mm size. However, it's always a good idea to have a conversion chart handy for quick reference and to double-check for accuracy, especially when dealing with critical applications.

Advantages and Disadvantages of Using SAE Equivalents

Let's explore the pros and cons of using SAE equivalents when working with metric fasteners:

| Advantages | Disadvantages |

|---|---|

| Convenience when SAE tools are more readily available. | Potential for a looser or tighter fit compared to the exact metric size. |

| Can be a temporary solution in a pinch. | Risk of rounding off the fastener if the fit is not precise enough. |

To avoid any potential issues, remember that using the correct size and system for your fasteners is always the safest and most reliable approach. However, in a pinch, knowing your SAE equivalents can be a helpful workaround.

In conclusion, while the world of metric and SAE fasteners might seem like two separate languages, understanding the relationship between them, especially the SAE equivalent to 8mm, can make your DIY or professional projects smoother and more efficient. Armed with this knowledge, you'll be able to confidently tackle any fastener challenge that comes your way, bridging the gap between metric and SAE with ease.

Sae To Metric Wrench Conversion Chart - The Brass Coq

Socket Size Chart In Order - The Brass Coq

Allen Wrench Conversions Chart - The Brass Coq

Printable Wrench Size Chart - The Brass Coq

What Size Drill Bit Is Equivalent To 8Mm - The Brass Coq

Printable Standard Wrench Size Chart - The Brass Coq

General Engineering, Civil Engineering, Tap Chart, Thread Size Chart - The Brass Coq

Printed Circuit Board Drill Sizes - The Brass Coq

sae equivalent to 8mm - The Brass Coq

Standard Socket Size Chart In Order - The Brass Coq

Allen Wrench Conversions Chart - The Brass Coq

Printable Socket Size Chart Metric And Standard - The Brass Coq

THE ULTIMATE WRENCH SIZE CONVERSION CHART - The Brass Coq

Metric To Standard Conversion Chart Wrenches - The Brass Coq

Bolt To Wrench Size Chart - The Brass Coq