Ever found yourself staring at a 14mm bolt, desperately wishing you knew its SAE counterpart? You're not alone! The world of fasteners can feel like a confusing maze, especially when juggling between metric and SAE measurements. This confusion is particularly common when dealing with nuts and bolts, often leading to frustrating project delays and mismatched tools.

But fear not, understanding the SAE equivalent of metric sizes, like 14mm, is simpler than it seems. This article will serve as your guide to deciphering these measurements and understanding their applications.

First, let's demystify the acronyms. SAE stands for the Society of Automotive Engineers, a body known for setting standards in various industries, including automotive. On the other hand, the metric system, with its millimeters and centimeters, needs no introduction, being the globally dominant system of measurement.

The SAE and metric systems developed independently, leading to different measurement standards for fasteners. While a direct, one-to-one conversion isn't always possible, there are commonly accepted equivalents. Finding the SAE equivalent of a 14mm bolt is crucial, especially when working on vehicles or machinery that utilize both systems. Using the wrong size can lead to loose fittings, stripped threads, or worse, component failure.

So, how do you navigate this measurement maze? The closest SAE equivalent to a 14mm bolt is a 9/16-inch bolt. However, this is an approximation, and a 14mm wrench might not fit snugly on a 9/16-inch bolt due to slight variations in tolerances. It's always best to double-check compatibility and, if possible, test the fit before fully tightening.

Advantages and Disadvantages of Using SAE Equivalents

While using the closest SAE equivalent can be a quick fix, it's important to understand the potential advantages and disadvantages:

| Advantages | Disadvantages |

|---|---|

| Readily available tools in regions where SAE is prevalent | Not a perfect fit, may lead to loosening or damage over time |

| Can be a temporary solution in a pinch | May not provide the same level of torque or clamping force |

Best Practices for Dealing with Metric and SAE Fasteners

To ensure the longevity and safety of your projects, follow these best practices:

- Identify the thread pitch: Besides the diameter, the thread pitch (distance between threads) is also critical for a proper fit. Ensure both the metric and SAE fasteners have compatible thread pitches.

- Use a thread pitch gauge: This tool helps accurately determine the thread pitch of your fastener, avoiding mismatches.

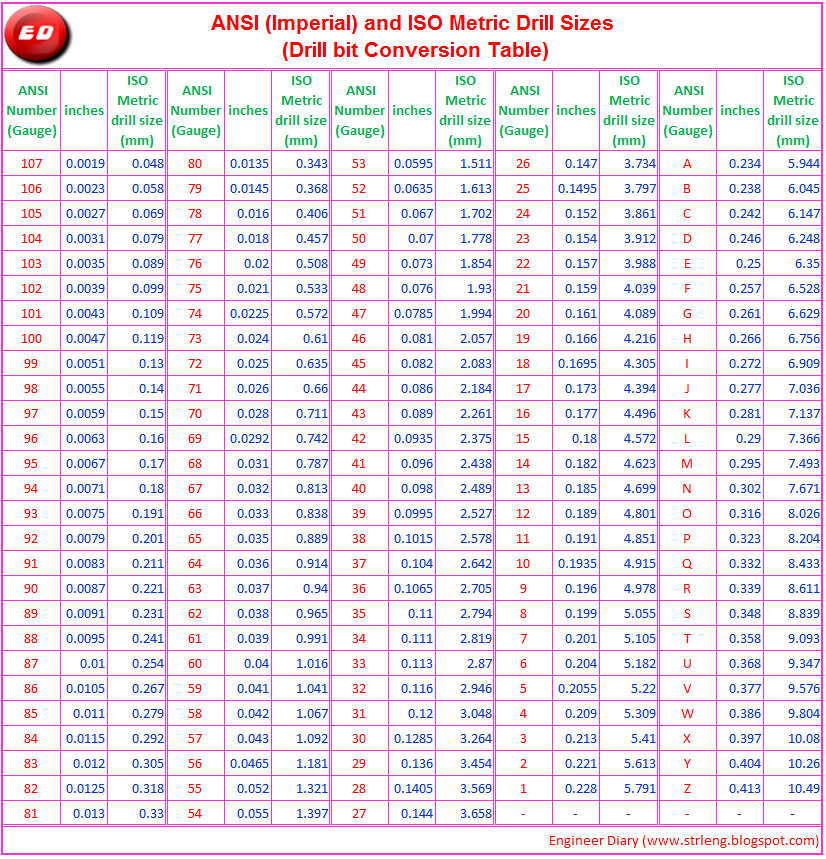

- Consult conversion charts: Use reliable conversion charts to find the closest equivalents, but remember these are approximations.

- Test the fit: Before fully tightening, test if the wrench or socket fits snugly on the fastener to avoid rounding off the edges.

- When in doubt, use the original system: If possible, stick to the original measurement system used in the application to ensure the best fit and performance.

Common Questions and Answers

Q1: Can I use a 9/16-inch wrench on a 14mm bolt?

It's not recommended. While they are close in size, the fit might not be precise, leading to potential damage.

Q2: Where can I find reliable conversion charts?

Reputable online engineering resources, tool manufacturers' websites, and engineering handbooks often provide accurate conversion charts.

Q3: What are the risks of using the wrong size fastener?

Using the wrong size can lead to stripped threads, loose fittings, compromised structural integrity, and even component failure.

Tips and Tricks

- Keep a set of both metric and SAE wrenches and sockets handy, especially when working on vehicles or machinery.

- Label your tools clearly to avoid confusion.

- When purchasing fasteners, buy a few extras in the correct size to avoid delays due to lost or damaged ones.

Understanding the nuances of SAE and metric equivalents is crucial for anyone who works with tools and fasteners. While the 9/16-inch size is a close approximation for a 14mm bolt, it's essential to prioritize accuracy and proper fit to ensure the safety and longevity of your projects. By following the best practices outlined in this article and using the right tools, you can confidently navigate the world of fasteners and avoid the frustration of mismatched sizes. Remember, taking the time to select the correct fastener is always a worthwhile investment in the success of your endeavors.

Printable Standard Wrench Size Chart - The Brass Coq

Metric Box Wrench Sizes at Ella Low blog - The Brass Coq

Printable Socket Size Chart Metric And Standard - The Brass Coq

Printable Wrench Size Chart - The Brass Coq

Printable Standard Wrench Size Chart - The Brass Coq

Standard Socket Size Chart - The Brass Coq

Wrench Size Chart Pdf - The Brass Coq

Available one yearn start, something ability being former up season - The Brass Coq

Allen Wrench Conversions Chart - The Brass Coq

Printable Socket Size Chart Metric And Standard - The Brass Coq

sae equivalent to 14mm - The Brass Coq

Printed Circuit Board Drill Sizes - The Brass Coq