Ever glanced at your fuel gauge, only to be met with a baffling reading? Perhaps it's stubbornly stuck on full, plummeting to empty faster than you can fill up, or fluctuating wildly between extremes. The culprit often lies within the gas gauge sending unit, a small but crucial component responsible for communicating your fuel level to the dashboard gauge. Understanding how to test this unit can save you from unexpected roadside stops, costly misdiagnoses, and general fuel-related anxieties.

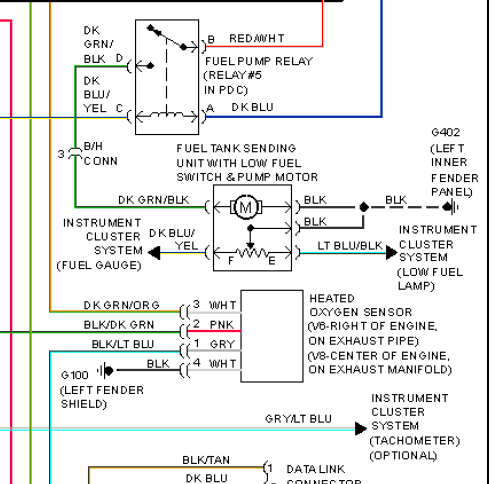

The gas gauge sending unit, often referred to as the fuel level sensor, is submerged within the fuel tank. It works in conjunction with a float, which rises and falls with the fuel level. This movement adjusts a variable resistor within the sending unit, altering the electrical resistance and sending a corresponding signal to the fuel gauge. Accurately testing the sending unit involves verifying this entire process, ensuring a precise reflection of the fuel level.

The development of fuel level sensors has mirrored the evolution of automobiles themselves. Early systems were rudimentary, relying on simple float mechanisms and often providing imprecise readings. Modern sending units are far more sophisticated, employing advanced electronic components for enhanced accuracy and reliability. This progress has made diagnosing faulty sending units more complex, but also more crucial for maintaining the smooth operation of modern vehicles.

Checking the fuel sending unit is vital for maintaining accurate fuel level readings. An incorrectly functioning unit can lead to several issues, including running out of fuel unexpectedly, inaccurate fuel consumption calculations, and unnecessary trips to the mechanic. A faulty sending unit can also mask other underlying fuel system problems, making accurate diagnostics difficult.

Understanding how your fuel gauge system operates is the first step towards effective troubleshooting. The sending unit isn't the only potential culprit for erratic fuel gauge readings. Wiring issues, a faulty gauge itself, or even a damaged float can all contribute to inaccurate readings. Proper testing procedures help isolate the source of the problem and prevent unnecessary part replacements.

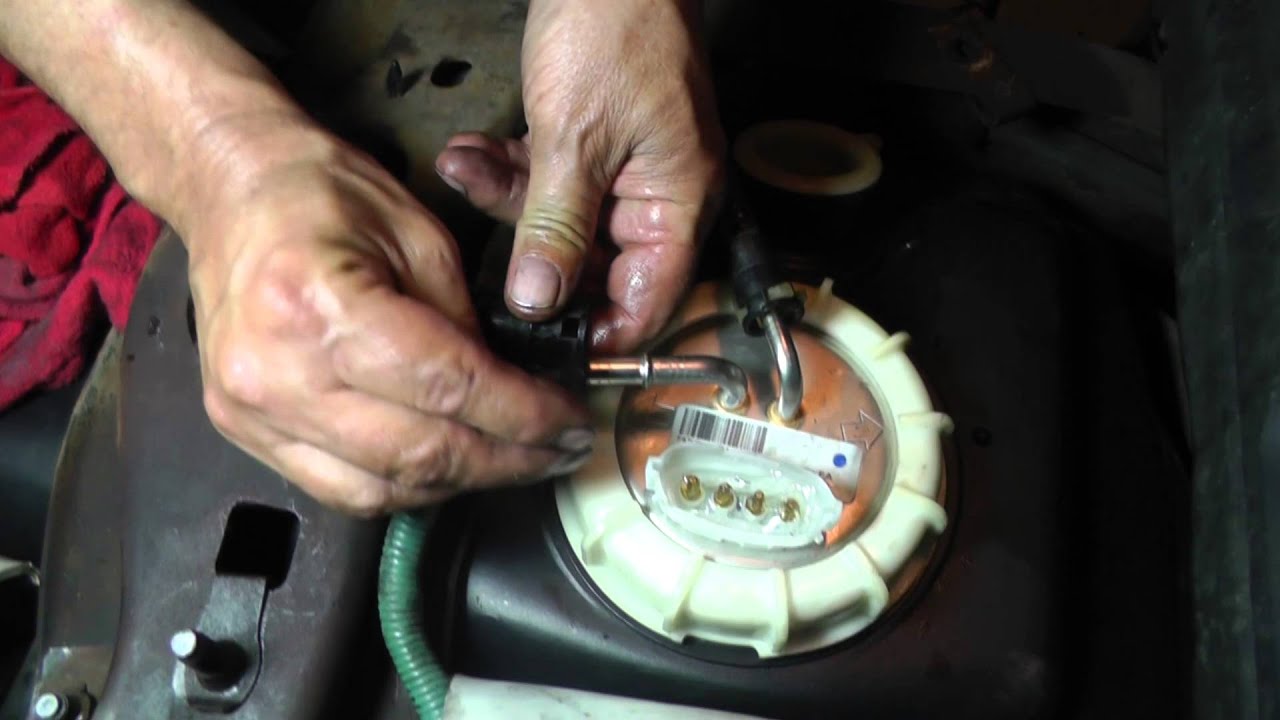

There are several ways to check your sending unit. One common method is to observe the fuel gauge reading while manually moving the float arm. Another involves using a multimeter to measure the resistance of the sending unit at different fuel levels. More advanced diagnostic tools can be used to directly monitor the signal sent from the unit to the gauge.

For example, if you have a half-full tank and your multimeter reading matches the resistance specified for a half-full tank in your vehicle's service manual, then your sending unit is likely functioning correctly. Conversely, if your tank is half full but the resistance reading corresponds to a full or empty tank, it suggests a problem with the sending unit.

Accurately diagnosing fuel gauge problems offers several benefits. First, it prevents running out of fuel, a frustrating and potentially dangerous situation. Second, it ensures accurate fuel consumption calculations, allowing you to monitor your vehicle's efficiency and identify potential problems early on. Third, it saves you money by avoiding unnecessary repairs or replacements.

Step-by-step guide to testing your fuel sending unit: 1. Disconnect the wiring harness from the sending unit. 2. Use a multimeter to measure the resistance between the sending unit terminals. 3. Consult your vehicle’s service manual for the correct resistance values at different fuel levels. 4. Compare your readings with the specified values. 5. If the readings don't match, replace the sending unit.

Advantages and Disadvantages of Testing Your Gas Gauge Sending Unit

| Advantages | Disadvantages |

|---|---|

| Avoid running out of gas | Can be time-consuming |

| Accurate fuel consumption data | Requires some technical knowledge |

| Save money on unnecessary repairs | May require specialized tools |

Five best practices: 1. Consult your vehicle's service manual. 2. Use the correct testing procedures. 3. Use a high-quality multimeter. 4. Handle the sending unit carefully. 5. If in doubt, seek professional assistance.

Frequently Asked Questions: 1. Why is my fuel gauge not working? Possible causes include a faulty sending unit, wiring problems, or a bad gauge. 2. How do I know if my sending unit is bad? Testing with a multimeter can confirm a faulty sending unit. 3. Can I test my sending unit without removing it? Sometimes, but accessing the sending unit directly is often necessary. 4. What tools do I need to test my sending unit? A multimeter is the primary tool needed. 5. How much does a new sending unit cost? Prices vary depending on the vehicle. 6. How long does it take to replace a sending unit? Replacement time varies depending on vehicle accessibility. 7. Can I replace the sending unit myself? It's possible with the right tools and experience. 8. Where can I find more information about my vehicle's fuel system? Your vehicle’s service manual is the best source of information.

Tips and tricks: Always disconnect the negative battery cable before working on any electrical components. Be careful not to damage the float arm when handling the sending unit. Use dielectric grease on the electrical connections to prevent corrosion.

In conclusion, mastering the art of testing your gas gauge sending unit empowers you to take control of your vehicle's fuel system. From avoiding unexpected empty tanks to ensuring accurate fuel consumption calculations, the benefits are numerous. By understanding the function and testing procedures of the fuel sending unit, you can save money, time, and frustration. This knowledge is invaluable for all drivers, enabling them to maintain their vehicles efficiently and avoid potentially stressful situations. Don't let a faulty fuel gauge dictate your journey; equip yourself with the knowledge and tools to ensure accurate fuel readings and enjoy a smooth, worry-free driving experience. Take the time to familiarize yourself with the specifics of your vehicle’s fuel system and embrace the confidence that comes with knowing how to troubleshoot and maintain it effectively. This proactive approach to vehicle maintenance will undoubtedly contribute to a more enjoyable and reliable driving experience.

Mgb Fuel Gauge Wiring Diagram - The Brass Coq

Marine Fuel Gauge Wiring Diagram Free Download - The Brass Coq

Boat Fuel Sender Wiring Gauge - The Brass Coq

Trouble Shooting Gauges in 2024 - The Brass Coq

Wiring Boat Fuel Gauge - The Brass Coq

Chevy S10 Fuel Pump Ground Wire - The Brass Coq

Buy High Resolution Marine Fuel Sending Unit with Gauge 6150mm - The Brass Coq

Wiring Boat Fuel Gauge - The Brass Coq

how to test gas gauge sending unit - The Brass Coq

Boat Fuel Tank Gauge Wiring Diagram - The Brass Coq

Fuel Pump Gas Gauge Not Working at Connie Keppler blog - The Brass Coq

how to test gas gauge sending unit - The Brass Coq

How To Test A Fuel Gauge Sending Unit - The Brass Coq

How To Change A Fuel Sending Unit - The Brass Coq

Gas Sending Unit Wiring Diagram - The Brass Coq